Precision Conical Screw Mixer | 30% Faster Powder & Liquid Blending (GMP/ATEX Certified)

Intro:

Title Tag: Conical Screw Mixer | Industrial Mixing Equipment for Powder & Liquids

Meta Description: Premium conical screw mixer for precision blending of powders, liquids & fibers. ISO-certified industrial mixer with 360° mixing action, trusted by pharmaceutical & chemical industries. Request custom solution now.

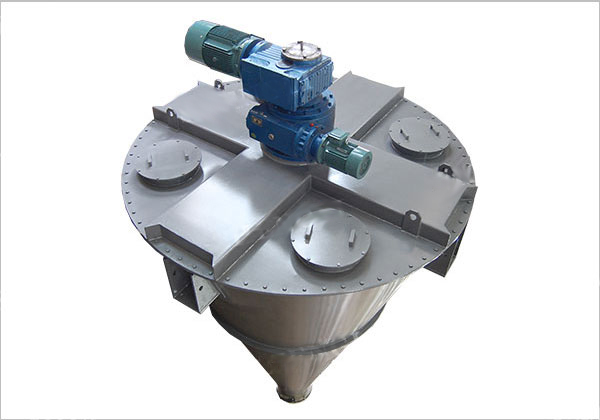

【Industrial-Grade Conical Screw Blender】

Precision Mixing Technology for Demanding Applications

Our conical screw mixer delivers unmatched material compatibility across 25+ industries. Engineered for pharmaceutical compounding, chemical processing, and food-grade blending, this industrial mixer features:

✔ 360° Helical Mixing Motion – Ensures complete homogeneity without material stratification

✔ Temperature-Sensitive Processing – Maintains product integrity during heat-sensitive blending

✔ Multi-Phase Compatibility – Handles solid-solid (powder to powder), solid-liquid, and liquid-liquid mixtures

✔ Size-Versatile Design – Processes materials from 50μm ultrafine powders to 5mm coarse granules

✔ CIP/SIP Ready – Compliant with GMP standards for pharmaceutical and food production

Technical Advantages:

• 15-30% Faster Mixing Cycles vs. conventional blenders

• 0.2% Residual Material Retention for batch consistency

• 304/316L Stainless Steel Construction

• ATEX-certified explosion-proof options

Industry Applications:

→ Pharmaceuticals: API blending, excipient mixing

→ Chemicals: Fertilizer production, polymer compounding

→ Food Processing: Powder flavor mixing, vitamin enrichment

→ Advanced Materials: Battery electrode materials, ceramic slurries

Конический шнековый смеситель ГОСТ Р | Смешивание порошков на 25% быстрее (GMP/ATEX)

Title Tag: Конический шнековый смеситель | Промышленное смесительное оборудование

Meta Description: Высокоэффективный конический смеситель для порошков, жидкостей и волокнистых материалов. Сертифицированное оборудование для фармацевтики и химической промышленности. Получите индивидуальное решение.

【Промышленный Шнековый Смеситель Конического Типа】

Технология Прецизионного Смешивания

Наш конический шнековый смеситель обеспечивает:

✔ Полное смешение за 3-7 минут

✔ Работа с материалами от 50 мкм до 5 мм

✔ Система CIP для фармацевтического производства

✔ Варианты исполнения из стали AISI 316L

Ключевые преимущества:

• На 25% меньше энергопотребления

• Сертификаты GMP и ГОСТ Р

• Взрывозащищенные модификации

• Автоматическая система очистки

Сферы применения:

✓ Фармацевтика: смешивание активных веществ

✓ Химическая промышленность: производство удобрений

✓ Пищевое производство: создание смесей специй

Working principle:

Title Tag :

Asymmetric Spiral Mixer | High-Efficiency Industrial Blending Equipment (ISO/GMP Certified)

Meta Description :

Patented dual-spire mixer achieves 360° material circulation with 40% faster homogenization. ATEX-compliant design for chemical/pharmaceutical industries. Request technical whitepaper.

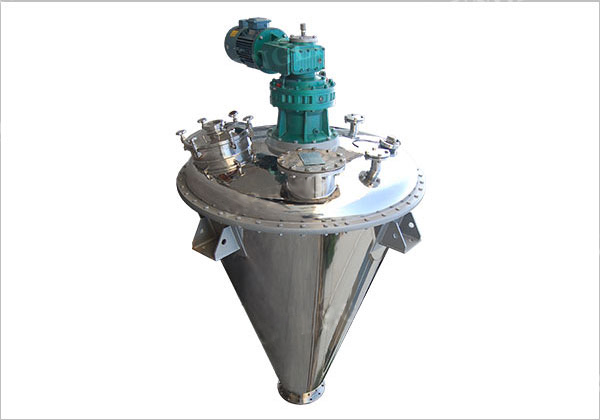

【Industrial Mixing Technology Reimagined】

Core Innovation: Dual-Axis Counterflow Blending System

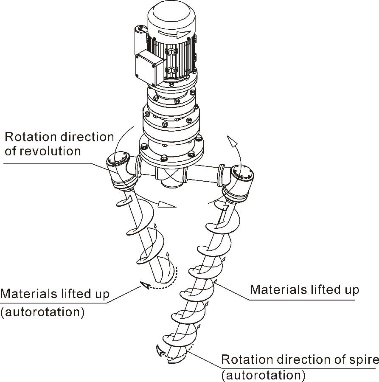

Our asymmetric spiral mixer revolutionizes bulk material processing through three synergistic motions:

-

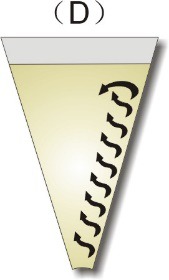

Vertical Lift Dynamics

-

15 RPM autorotation of upper spire creates upward material flow along barrel wall

-

7 RPM revolution of lower spire generates centrifugal dispersion (see Fig.A)

-

-

Radial Material Renewal

-

0.5-3mm adjustable gap between spires ensures 92% particle contact rate

-

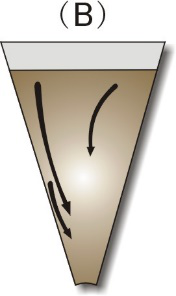

Continuous ejection-reabsorption cycle prevents stratification (Fig.B)

-

-

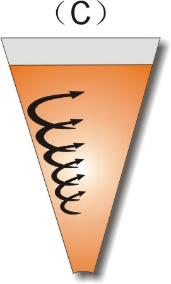

Convergent Downward Flow

-

Central vortex achieves 18m³/hour throughput with ≤0.3% residue

-

Technical Superiority

✔ 45% Faster Cycle Times vs. traditional ribbon mixers

✔ GMP/ISO 9001 Certified with CIP/SIP compatibility

✔ Material Versatility

-

Handles powders (20μm-5mm)

-

Processes viscous pastes (up to 150,000 cP)

-

Compatible with shear-sensitive fibers

Industry Applications

→ Pharmaceuticals: API-excipient blending (Fig.E)

→ Chemicals: Catalyst preparation with 99.8% uniformity

→ Food: Spice homogenization meeting HACCP standards

[CTA Section]

[Download 3D Animation] See Counterflow Mechanism in Action

[Request Custom Quote] Get Mixing Efficiency Analysis Report

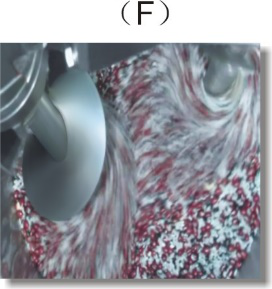

The rapid autorotation and revolution of the two asymmetric spires in the mixer cause materials to be lifted upward, forming two asymmetric spiral material flows along the barrel wall from the bottom to the top (see Figs. A and B). Driven by the rotating arm, the revolutionary motion of the spires enables external materials to enter the mixing zone at varying degrees – some are improperly lifted while others are ejected from the stud. This ensures continuous renewal and dispersion of materials throughout the circumferential orientation. The two upward material flows converge toward the central countersink, forming a downward flow that replenishes the bottom cavity, thereby establishing a counter-flow circulation (see Figs. A, B, C, D). Through the compounding of these motions, materials achieve rapid homogeneous mixing and maintain a high mixing degree (see Figs. E and F).

Быстрое автономное вращение и оборот двух асимметричных шпилей смесителя поднимают материалы вверх, формируя два асимметричных спиральных потока вдоль стенок барабана снизу вверх (см. Рис. A и B). Вращательное движение шпилей, приводимых в действие поворотным рычагом, позволяет внешним материалам проникать в зону смешивания с разной интенсивностью – часть неправильно поднимается, а часть выбрасывается из рабочей зоны. Это обеспечивает постоянное обновление и дисперсию материалов по всей окружности. Два восходящих потока материала сходятся к центральному углублению, образуя нисходящий поток, который заполняет нижнюю полость, создавая встречную циркуляцию (см. Рис. A, B, C, D). Благодаря комбинации этих движений достигается быстрое однородное смешивание материалов с высокой степенью гомогенизации (см. Рис. E и F).

Title Tag:

Промышленный смеситель асимметричного типа | Оборудование для смешивания сыпучих материалов

Meta Description:

Высокоскоростной смеситель с двойным шнеком для фармацевтики и химической промышленности. Сертификаты ГОСТ Р и GMP. Запросите спецификации.

【Инновационная Система Смешивания】

Принцип работы:

-

Вертикальный подъем материала

-

Верхний шнек: 15 об/мин для формирования восходящего потока

-

Нижний шнек: 7 об/мин для дисперсии частиц (Схема А)

-

-

Радиальное обновление состава

-

Регулируемый зазор 0.5-3 мм между шнеками

-

Цикл повторного захвата частиц (Схема Б)

-

-

Центробежная циркуляция

-

Производительность 18м³/ч с остатком ≤0.3%

-

Преимущества:

• На 40% быстрее традиционных смесителей

• CIP-система для фармацевтического производства

• Варианты из стали AISI 316L

Применение:

✓ Химическая промышленность: производство удобрений

✓ Пищевая отрасль: смешивание специй

✓ Металлургия: приготовление керамических суспензий

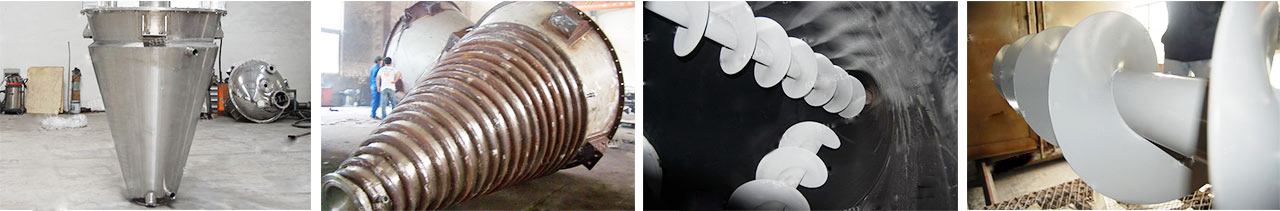

Product introduction

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; different material can also be used in parts, between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel can be sandblasting, wiredrawing, polishing, mirror polishing

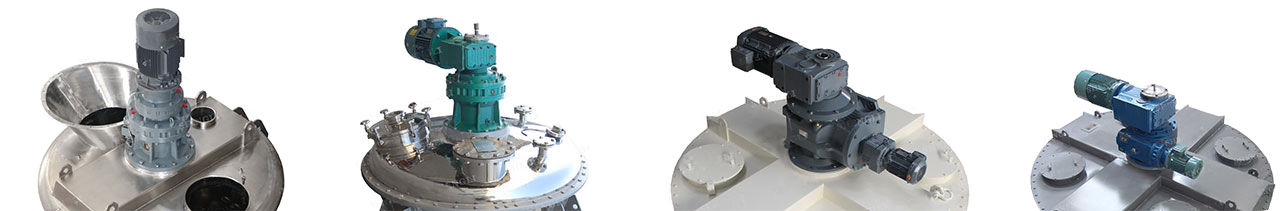

2.Reliable driven unit

The driven unit and power is varied according to different raw material, starting method, and processing.

Double screw conical mixer is equipped with appropriative double output reducer, which combines pinwheel, gear and warm and gear.

3.Excellent discharging unit

Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.The surface of the valve match the track of the bottom of screw, to reduce the mixing dead zone to the maximum, and to make the largest discharging area, so as to make sure no leftover. Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.Plum-blossom dislocation valve is easy to operate and control the discharging speed

4.Powerful auxiliary components

Equipped with circulation medium of jacket, the double screw conical mixer can realize the temperature control in mixing process.

In the mixer barrel, the part contact with material can coat some antiriot, anti-caking and metal isolation material according to different ingredient. In some severe wear conditions, the screw surface can be overlaid by some wear proof alloy.

If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

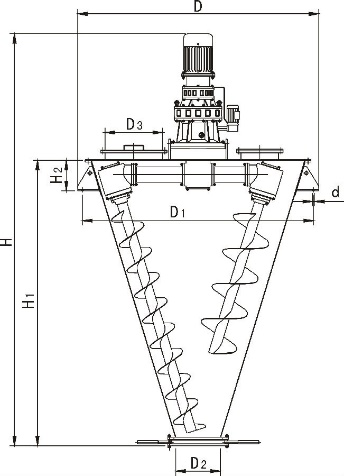

Specification

Standard Features:

- Volume: 10-20000L

- Stainless Steel or Carbon Steel

- Screw agitator for center discharge

- Designed for normal temperature and normal atmospheric pressure

- Feed Nozzle

- Dust Nozzle

- Manually operated or Pneumatic operated dislocated valve

- Packing Seal

- Safety limit switch on man hole

Optional Features:

- Carbon Steel, Stainless Steel 304, Stainless Steel 316L

- Internal pressure

- Sanitary type construction

- Dislocated valve, butterfly valve, slide gate valve, ball valve

- Horsepower to suit higher density materials

- Explosion-proof motors

- Controls such as variable frequency drives, motor starters and operator stations are available

- Spray nozzles for liquid introduction

- Jacket for heating or cooling

| VZH | VZH | VZH | VZH | VZH | VZH | VZH | VZH | VZH | VZH | VZH | VZH | |

| 0.01 | 0.015 | 0.02 | 0.03 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.5 | 0.8 | 1 | |

| Full volume | 0.01 | 0.015 | 0.02 | 0.03 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.5 | 0.8 | 1 |

| Productivity (t/h) | 0.01-0.02 | 0.015-0.03 | 0.02-0.05 | 0.03-0.07 | 0.05-0.1 | 0.1-0.2 | 0.15-0.3 | 0.2-0.8 | 0.3-1 | 0.5-1.5 | 0.8-2 | 1.5-3 |

| Loading coefficient | 0.6 | |||||||||||

| Msterial graininess | ≥20 | |||||||||||

| Mixing evenness | Relation deviation<1.5 | |||||||||||

| Total power(Kw) | 0.37 | 0.37 | 0.55 | 0.55 | 0.75 | 1.5 | 1.5 | 2.2 | 3 | 3 | 4 | 4 |

| Autorotation | 100 | 100 | 100 | 100 | 100 | 143 | 143 | 143 | 143 | 143 | 57 | 57 |

| Revolution | 2 | |||||||||||

| Working pressure | micro-pressure | |||||||||||

| Out-from dimension | 455 | 470 | 492 | 524 | 587 | 708 | 782 | 888 | 990 | 1156 | 1492 | 1600 |

| Total height(H) | 982 | 1006 | 1020 | 1168 | 1272 | 1498 | 1620 | 1875 | 2040 | 2314 | 2576 | 2736 |

| Central distance of support(D1) | 410 | 425 | 440 | 472 | 535 | 648 | 724 | 808 | 910 | 1076 | 1392 | 1500 |

| Height harm support to beduct covert(H2) | 122 | 122 | 135 | 135 | 135 | 150 | 150 | 180 | 180 | 180 | 275 | 275 |

| Size of feed port(D3) | Ф80 | Ф80 | Ф80 | Ф80 | Ф80 | Ф140 | Ф140 | Ф140 | Ф180 | Ф200 | Ф250 | Ф300 |

| Size of discharge port(D2) | Ф100 | Ф100 | Ф110 | Ф125 | Ф125 | Ф150 | Ф150 | Ф230 | Ф230 | Ф230 | Ф300 | Ф300 |

| Bucket height(H1) | 505 | 528 | 542 | 578 | 682 | 816 | 938 | 955 | 1120 | 1390 | 1572 | 1747 |

| Aperture of support(d) | Ф14 | Ф14 | Ф16 | Ф16 | Ф16 | Ф18 | Ф18 | Ф18 | Ф18 | Ф18 | Ф22 | Ф22 |

| Equipment weight(Kg) | 100 | 110 | 120 | 130 | 150 | 210 | 250 | 500 | 550 | 600 | 900 | 1200 |

| VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | VSH-B | |

| 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | |

| Full volume | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 |

| Productivity (t/h) | 2-4.5 | 2.5-5 | 4.0-7 | 5-7.5 | 5-10 | 6-13 | 7.5-15 | 10-20 | 10-25 | 12-28 | 15-30 | 20-40 |

| Loading coefficient | 0.6 | |||||||||||

| Msterial graininess | ≥20 | |||||||||||

| Mixing evenness | Relation deviation<1.5 | |||||||||||

| Total power(Kw) | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 30 |

| Autorotation | 57 | 57 | 57 | 57 | 57 | 57 | 57 | 57 | 57 | 57 | 57 | 57 |

| Revolution | 2 | |||||||||||

| Working pressure | micro-pressure | |||||||||||

| Out-from dimension | 1780 | 1948 | 2062 | 2175 | 2435 | 2578 | 2715 | 2792 | 3000 | 3195 | 3438 | 3775 |

| Total height(H) | 3132 | 3400 | 3425 | 3605 | 4416 | 4660 | 4876 | 5350 | 5647 | 5987 | 6364 | 7144 |

| Central distance of support(D1) | 1680 | 1848 | 1962 | 2075 | 2325 | 2468 | 2605 | 2672 | 2860 | 3042 | 3276 | 3640 |

| Height harm support to beduct covert(H2) | 275 | 275 | 275 | 275 | 320 | 320 | 320 | 500 | 500 | 500 | 500 | 500 |

| Size of feed port(D3) | Ф300 | Ф350 | Ф350 | Ф350 | Ф400 | Ф400 | Ф400 | Ф400 | Ф500 | Ф500 | Ф500 | Ф500 |

| Size of discharge port(D2) | Ф300 | Ф300 | Ф400 | Ф400 | Ф400 | Ф400 | Ф400 | Ф450 | Ф450 | Ф450 | Ф450 | Ф560 |

| Bucket height(H1) | 2042 | 2316 | 2340 | 2522 | 2890 | 3125 | 3340 | 3707 | 4004 | 4310 | 4687 | 5060 |

| Aperture of support(d) | Ф22 | Ф22 | Ф22 | Ф22 | Ф26 | Ф26 | Ф26 | Ф28 | Ф28 | Ф28 | Ф28 | Ф30 |

| Equipment weight(Kg) | 1350 | 1500 | 1800 | 2100 | 2500 | 3000 | 3500 | 3800 | 4300 | 4500 | 4900 | 5500 |

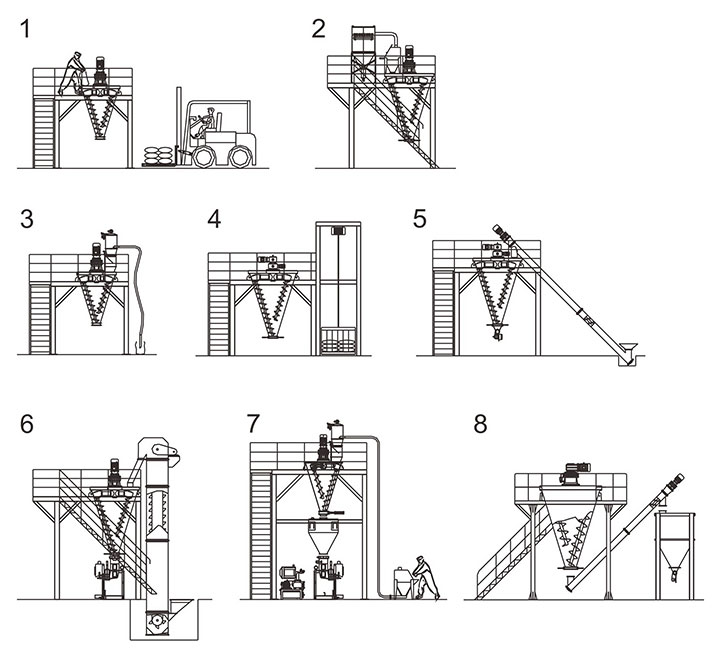

Accessory project

Configuration 1: conical mixer with vacuum feeder

Configuration 2: with cargo elevator, manually feeding

Configuration 3: conical mixer with screw conveyor feeder

Configuration 4: conical mixer with vacuum feeder

Configuration 5: with cargo elevator, manually feeding

Configuration 6: conical mixer with screw conveyor feeder

Configuration 7: simple production line with conical mixer, bucket elevator and auto-packing machine.

Configuration 8: multi-level platform, manually undoing the bag, vacuum feeding, storage and auto-packing

Configuration 9: platform for conical mixer, manually feeding, conveying mixed material to silo, and packing.

Download

Matching parts

A、Mixing Effect

The standard double screws cone-shape mixer is equipped with two agitating augers, yet single(a long auger), double(two dissymmetrical augers with different length) or triple(three symmetrical screws with two long and one short) augers is adopted in fact according to the size of the device; theoretically, more angle augers there are, better the mixing effect is.

B、Cooling and heating

Cool or heat the materials through feeding the cold or hot medium into the jacket which is added to the outside of the cylinder of the mixer. Pump industrial water for cooling and steam or heat oil heated by electricity for heating.

C、Liquid-adding mixing

The mix of injecting liquid can be achieved by connecting the atomized spray nozzle with spray pipe which is inserted in the intermediate axle location of the mixer. With choosing the specific materials, the mix of powder and liquid can be conducted by injecting acid or alkali liquid.

D、Compression Resistance

The cover of the cylinder can be made as the shape of a dome, deceasing residue to clean easily while improving compressive strength of the mixer cylinder, which should be frequently used when pressure resistance cylinder is needed.

E、Negative Pressure Feeding

The cylinder of the mixer can be made as negative pressure chamber in specific process, which breathes the dry material with good fluidity in mixing chamber for mixing using soft pipe, without residue and pollution in the feeding segment.

F、Discharging Mode

The standard device typically uses plum flower-shaped “dislocation valve” that joints closely with the bottom of long screw to decrease mix dead angle effectively with two driving methods, manual and pneumatic. It can also use butterfly valve, ball valve, star-shape material discharging device, side discharge and so on according to the user’s requirements.